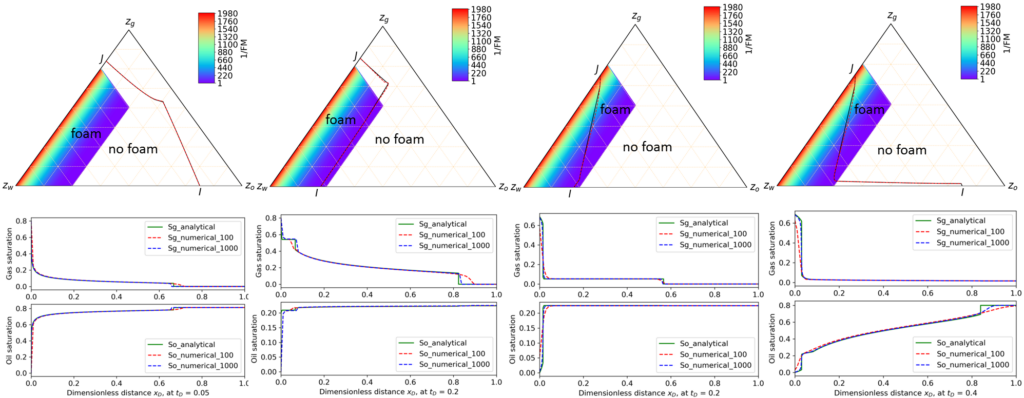

Foam improves significantly the sweep efficiency of gas injection. Foam-oil displacement in reservoirs involves strongly nonlinear physics, e.g. multiphase flow and transport with oil-foam interactions. The nonlinearity of this process challenges conventional simulation, which often translates into a high computational cost. To address this problem, we extend an Operator-Based Linearization (OBL) approach for simulation of foam EOR processes. Foam in porous media is described using an implicit-texture model with two flow regimes. The OBL approach is applied to reduce the nonlinearity of the foam problem. We validate the numerical-simulation results using three-phase fractional-flow theory for foam-oil flow. We conduct a series of numerical validation studies to investigate the accuracy and efficiency of the proposed approach. The OBL foam model shows good agreement with analytical solutions at different conditions and foam parameters as shown in Fig.16.

The validated foam model was used for predictive modelling of foam core experiments. The porosity of core was reconstructed based on the difference between wet and dry scans16. Next, simulation of oil displacement by foam was modelled and compared with experimental results17. As shown in Fig.17, foam creates oil banks which prevent gas from escaping. In overall, both simulation and experimental results have a reasonably good match.